After posts the previous two days on our team's modeling process for the Kent State College of Architecture and Environmental Design's new building, see Alan + Philip's joint post on the in-house model making process and Andrew's story of his experience on the level of collaboration between Bialosky + Partners Architects and Architecture Research Office, we thought it be proper to share a few pictures of the final model. The model, and other media, is now on display (along with the other three team's proposals) in the first floor of the Kent State University Library, through February 15th. Watch the video of the BPA + ARO team public presentation here: https://ksutube.kent.edu/playback.php?playthis=g929c9yz2 A recap of the public presentations, courtesy of Kent State: http://www.youtube.com/watch?v=gzl1JAZreno Press coverage of the CAED design competition:

- Kent Patch, Kent State Architecture College Proposals Unveiled. Vote BPA+ ARO!

- ArchDaily, Proposals Unveiled for Kent State's new Architecture College

- Cleveland Plain Delaer, Four Teams Unveil Conncepts in Competition to Design $40 Million Architecture School at KSU

- Kent Wired, Finalists Reveal Plans For New Architecture Building

- Archinect, Four Teams Unveil Concepts in Competition to Design $40 Million Architecture School at KSU

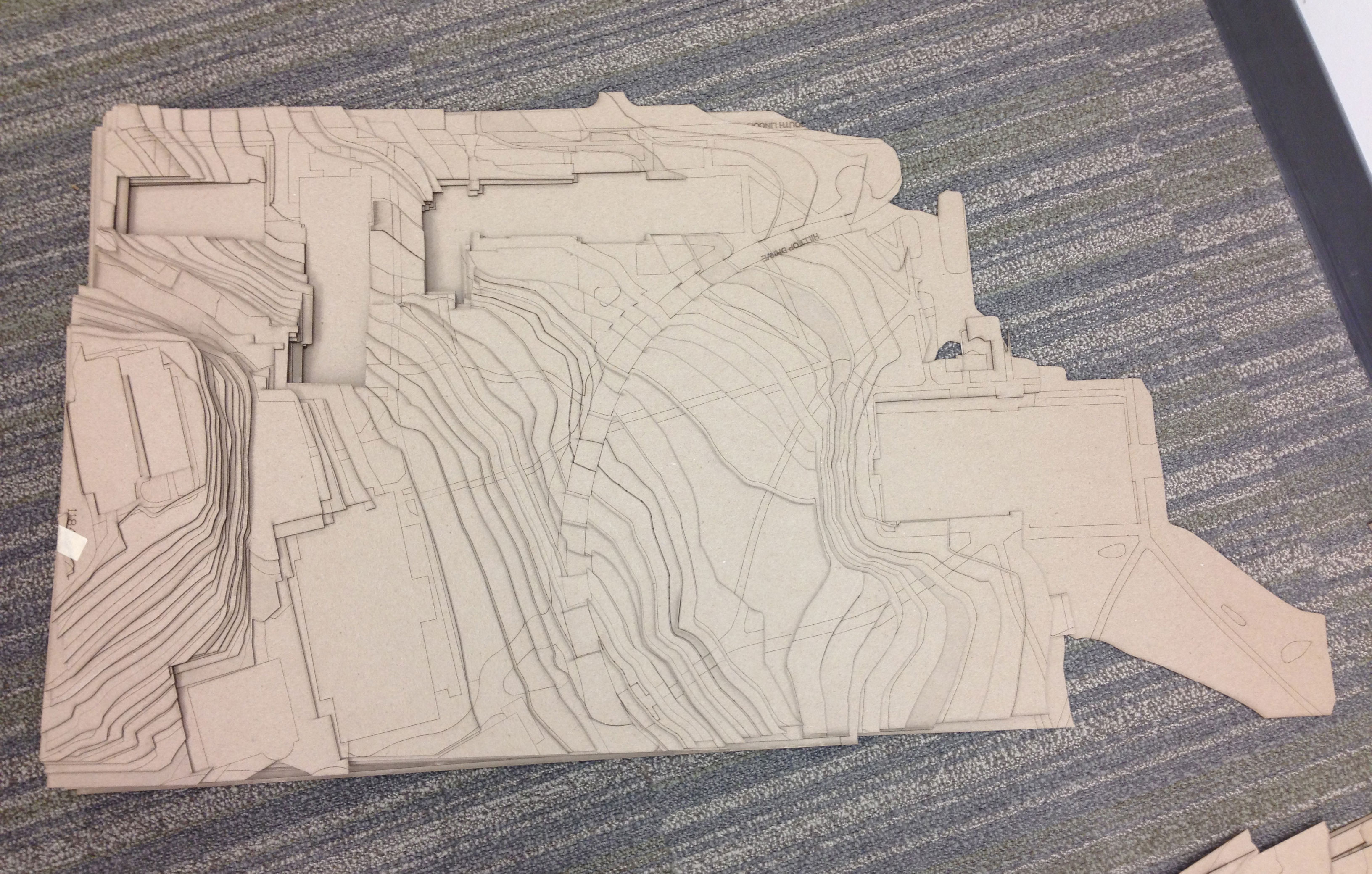

A collaborative model between Bialosky + Partners Architects and Architecture Research Office on display at the Kent State U. Main Library through February 15th.

The laser cut components do not output a model ready-to-go; we still needed to assemble it with great craft and with traditional tools (xacto knives, sobo glue, and the like) to create the final product. This assembly process still took a fair amount of time: sorting, carefully holding glued parts in place, and stacking dozens of pieces to create the contoured base with realistic topography. The buildings that surround the project site had also been laser cut, but are also sanded into typology profiles that express context and scale. Detailing 50+ buildings with roof slopes and profiles was a tedious process even with the use of shop tools to sand and cut the pieces, luckily only a little blood was shed in this part of production.

The laser cut components do not output a model ready-to-go; we still needed to assemble it with great craft and with traditional tools (xacto knives, sobo glue, and the like) to create the final product. This assembly process still took a fair amount of time: sorting, carefully holding glued parts in place, and stacking dozens of pieces to create the contoured base with realistic topography. The buildings that surround the project site had also been laser cut, but are also sanded into typology profiles that express context and scale. Detailing 50+ buildings with roof slopes and profiles was a tedious process even with the use of shop tools to sand and cut the pieces, luckily only a little blood was shed in this part of production.  To paint or not to paint the model became the final question. Everyone had an opinion on this topic and we discovered that the geographic location of one’s architecture school has something to do with it. East coast school = Paint, Midwest school = Not to Paint. So after 3-4 trips to the hardware store, the right color was found, the model was painted, and was ready for transport. Models, boards and other media are on display through February 15th at Kent State’s Main Library as part of Bialosky + Partners Architects Architecture Research Office’s collaborative proposal for the new Kent State University College of Architecture and Environmental Design.

To paint or not to paint the model became the final question. Everyone had an opinion on this topic and we discovered that the geographic location of one’s architecture school has something to do with it. East coast school = Paint, Midwest school = Not to Paint. So after 3-4 trips to the hardware store, the right color was found, the model was painted, and was ready for transport. Models, boards and other media are on display through February 15th at Kent State’s Main Library as part of Bialosky + Partners Architects Architecture Research Office’s collaborative proposal for the new Kent State University College of Architecture and Environmental Design.