Bialosky + Partners Architects is fighting hunger with what we do best - build!

We're participating in Cleveland 2013 Canstruction Design/Build competition which benefits The Cleveland Foodbank during their Harvest for Hunger Campaign. Canstruction, held in multiple cities worldwide, is a national charity of the design and construction industry created by the Society of Design Administration devoted to increasing public perception of hunger through gallery-style sculpture of canned goods in public locations.

With the help of our sponsors last year:

- Bialosky + Partners Architects raised a total of $4,475!

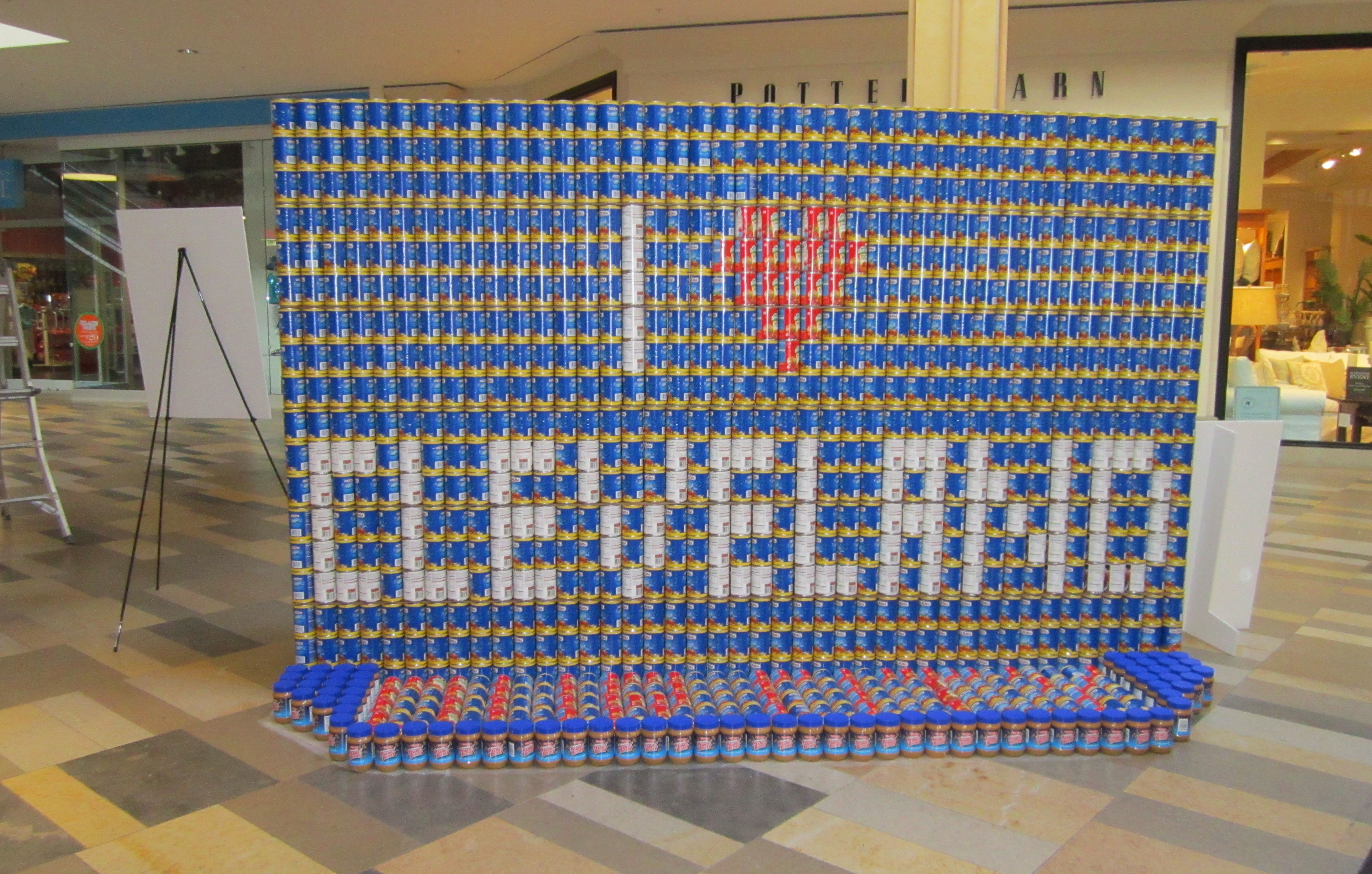

- Nonperishable items comprising our sculpture included: 3,645 canned goods and 515 jars of crunchy peanut butter, all of which were donated to the local food bank.

- After purchasing all required items for our sculpture, we were thrilled to have the ability to contribute a $900.00 cash donation to the Cleveland Foodbank above and beyond our canned goods donation.

- Our team’s design, featuring the Cleveland skyline, took Honorable Mention accolades in last year’s competition!

This year, we anticipate our sculpture to consist of 4,000 cans (or cost approximately $4,000). We respectfully request a donation of $250.00 as a company or $50.00 as an individual. However, your generosity at any amount will be greatly appreciated as we try and reach our goal. Your contributions will be recognized on signage next to our sculpture and featured in our Cleveland Design Blog. Please follow the link below to place a donation to help us build our structure!

DONATE HERE! (All donations are requested by March 4th)

Bialosky + Partners Architects 2012 Canstruction Sculpture of the Cleveland Skyline raised 3,645 cans and $900 for donation to The Cleveland Foodbank.

Our sculpture will be on display at Beachwood Place Mall from March 23 to April 1, 2013. We kindly request any assistance you could provide by Monday, March 4, 2013. Please accept our gratitude for your time, thought, and consideration. We look forward to the potential collaboration with you for this charitable event.

Needless to say the scene was fantastic, who wouldn't love working in NYC? My commute to work consisted of walking through the historic Soho District of cast iron facades felt like a step back in time. And working in such an iconic city was pretty surreal. The whole crew at ARO was great, I love going to new places and meeting new people and this was a perfect combination of both. The hardest part of adjusting to the new environment was learning everyone’s name. Thankfully on the fridge in their kitchenette there was a clever celebrity doppelgänger for most everyone in the office - it was pretty accurate and it served as a great cheat sheet for learning everyone’s name.

Needless to say the scene was fantastic, who wouldn't love working in NYC? My commute to work consisted of walking through the historic Soho District of cast iron facades felt like a step back in time. And working in such an iconic city was pretty surreal. The whole crew at ARO was great, I love going to new places and meeting new people and this was a perfect combination of both. The hardest part of adjusting to the new environment was learning everyone’s name. Thankfully on the fridge in their kitchenette there was a clever celebrity doppelgänger for most everyone in the office - it was pretty accurate and it served as a great cheat sheet for learning everyone’s name.

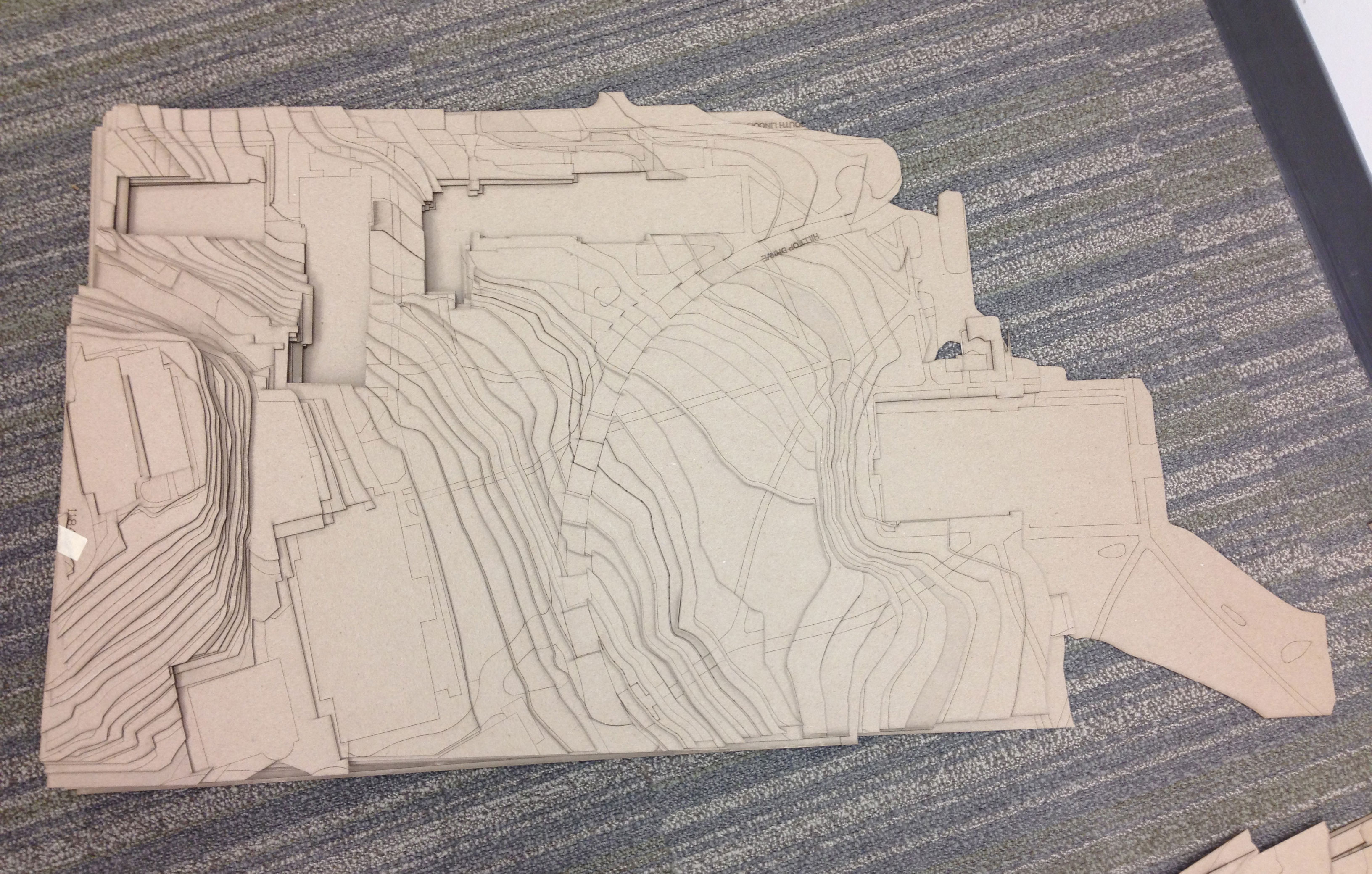

I knew from the moment I walked into the office that the physical model I was going to help construct was going to be killer. The entire office was surrounded by great presentation and diagrammatic models. The first day or so were getting the laser files ready, and over the next few days I became best friends with the laser cutter in the fabrication space. I went from hardly knowing anything about the settings for a laser cutter to knowing it possibly better than the back of my hand. A few things I learned that are important while using a laser cutter are: always tape down the basswood, stay hydrated, avoid wearing warm clothing like a sweater, and most importantly put on copious amounts of deodorant! Over the week it seemed like there wasn't a moment that something wasn't being built. Not only did the site and the architectural model need to be created, but since we were flying from NYC back to Ohio, a case to safely transport the site model needed to be created. As we worked on different portions of the model doing trials for roof materiality, façade articulations, and site patterns it was cool to see these isolated pieces of model began to piece together.

I knew from the moment I walked into the office that the physical model I was going to help construct was going to be killer. The entire office was surrounded by great presentation and diagrammatic models. The first day or so were getting the laser files ready, and over the next few days I became best friends with the laser cutter in the fabrication space. I went from hardly knowing anything about the settings for a laser cutter to knowing it possibly better than the back of my hand. A few things I learned that are important while using a laser cutter are: always tape down the basswood, stay hydrated, avoid wearing warm clothing like a sweater, and most importantly put on copious amounts of deodorant! Over the week it seemed like there wasn't a moment that something wasn't being built. Not only did the site and the architectural model need to be created, but since we were flying from NYC back to Ohio, a case to safely transport the site model needed to be created. As we worked on different portions of the model doing trials for roof materiality, façade articulations, and site patterns it was cool to see these isolated pieces of model began to piece together.  The last few hours before we left were definitely all hands on deck as all the finishing touches and last-minute tweaks were done to the models. Kai from ARO was helping me transport the model and as we got to the airport and I've never seen so many inquisitive faces. As we approached the counter I heard in a semi-joking voice, "Is there a pony in there!?" As we placed the "pony" box on the scale we thought for sure it was going to weigh less than 100 lbs. As the numbers went up and down on the scale it settled on 108. We talked with Margaret at the airline ticket counter and discussed our options. Although a large box, the dimensions were not a problem - it was those eight pounds over 100. Margaret started calling supervisors to see if there was any way we could get this on the plane, and after a few phone calls the unanimous answer was still no. I even asked if the box could take my seat on the plane. Realizing that getting on this plane was not going to happen, Kai and I both shook our heads realizing it was time to initiate plan B. Needing to keep the offices in the loop we started calling our co-workers at ARO + BPA letting them know that our plan B was in effect and a road trip to Kent, Ohio was about to commence. We rented a car and Ethan from ARO and I got ready for the 7 hour trip to Ohio (no worries, both of us had gotten sleep the night before) with an ETA of 3:30am! We passed by many scenic overlooks through the mountains of Pennsylvania ( none of which we could actually see) and were thankful there wasn't a blizzard or hurricane coming our way, unlike ARO's last two trips to Ohio. Arriving in Kent right on time we dropped off the model, and Ethan and I drove to the Canton Airport to drop him off and to pick up my car. He flew directly back about an hour later only getting to see the great interstates of Ohio, and I went to catch some zzz's. That evening at the public presentation in Kent it was really rewarding to see the results of the collaborative effort of both Bialosky + Partners Architects and Architecture Research Office and to have experienced the collaboration in Cleveland, New York City, and that night in Kent. I have no doubt this will be a lasting memory and will continue to be a highlight of my early career in architecture.

The last few hours before we left were definitely all hands on deck as all the finishing touches and last-minute tweaks were done to the models. Kai from ARO was helping me transport the model and as we got to the airport and I've never seen so many inquisitive faces. As we approached the counter I heard in a semi-joking voice, "Is there a pony in there!?" As we placed the "pony" box on the scale we thought for sure it was going to weigh less than 100 lbs. As the numbers went up and down on the scale it settled on 108. We talked with Margaret at the airline ticket counter and discussed our options. Although a large box, the dimensions were not a problem - it was those eight pounds over 100. Margaret started calling supervisors to see if there was any way we could get this on the plane, and after a few phone calls the unanimous answer was still no. I even asked if the box could take my seat on the plane. Realizing that getting on this plane was not going to happen, Kai and I both shook our heads realizing it was time to initiate plan B. Needing to keep the offices in the loop we started calling our co-workers at ARO + BPA letting them know that our plan B was in effect and a road trip to Kent, Ohio was about to commence. We rented a car and Ethan from ARO and I got ready for the 7 hour trip to Ohio (no worries, both of us had gotten sleep the night before) with an ETA of 3:30am! We passed by many scenic overlooks through the mountains of Pennsylvania ( none of which we could actually see) and were thankful there wasn't a blizzard or hurricane coming our way, unlike ARO's last two trips to Ohio. Arriving in Kent right on time we dropped off the model, and Ethan and I drove to the Canton Airport to drop him off and to pick up my car. He flew directly back about an hour later only getting to see the great interstates of Ohio, and I went to catch some zzz's. That evening at the public presentation in Kent it was really rewarding to see the results of the collaborative effort of both Bialosky + Partners Architects and Architecture Research Office and to have experienced the collaboration in Cleveland, New York City, and that night in Kent. I have no doubt this will be a lasting memory and will continue to be a highlight of my early career in architecture.

The laser cut components do not output a model ready-to-go; we still needed to assemble it with great craft and with traditional tools (xacto knives, sobo glue, and the like) to create the final product. This assembly process still took a fair amount of time: sorting, carefully holding glued parts in place, and stacking dozens of pieces to create the contoured base with realistic topography. The buildings that surround the project site had also been laser cut, but are also sanded into typology profiles that express context and scale. Detailing 50+ buildings with roof slopes and profiles was a tedious process even with the use of shop tools to sand and cut the pieces, luckily only a little blood was shed in this part of production.

The laser cut components do not output a model ready-to-go; we still needed to assemble it with great craft and with traditional tools (xacto knives, sobo glue, and the like) to create the final product. This assembly process still took a fair amount of time: sorting, carefully holding glued parts in place, and stacking dozens of pieces to create the contoured base with realistic topography. The buildings that surround the project site had also been laser cut, but are also sanded into typology profiles that express context and scale. Detailing 50+ buildings with roof slopes and profiles was a tedious process even with the use of shop tools to sand and cut the pieces, luckily only a little blood was shed in this part of production.  To paint or not to paint the model became the final question. Everyone had an opinion on this topic and we discovered that the geographic location of one’s architecture school has something to do with it. East coast school = Paint, Midwest school = Not to Paint. So after 3-4 trips to the hardware store, the right color was found, the model was painted, and was ready for transport. Models, boards and other media are on display through February 15th at Kent State’s Main Library as part of Bialosky + Partners Architects Architecture Research Office’s collaborative proposal for the new Kent State University College of Architecture and Environmental Design.

To paint or not to paint the model became the final question. Everyone had an opinion on this topic and we discovered that the geographic location of one’s architecture school has something to do with it. East coast school = Paint, Midwest school = Not to Paint. So after 3-4 trips to the hardware store, the right color was found, the model was painted, and was ready for transport. Models, boards and other media are on display through February 15th at Kent State’s Main Library as part of Bialosky + Partners Architects Architecture Research Office’s collaborative proposal for the new Kent State University College of Architecture and Environmental Design.