Ursuline College in Pepper Pike, OH, is launching phase one of an exciting new campus master plan, The Center for Creative and Healing Arts (CCHA). The state of the art 30,000 SF CCHA houses Art Therapy and Nursing programs and is targeted to open in Fall 2014. The project, acting as a front door to Ursuline, blends the college’s spare modern campus aesthetic with a welcoming warmth and contemporary playfulness. Purity of form and simply crafted details has been our project team’s design mantra.

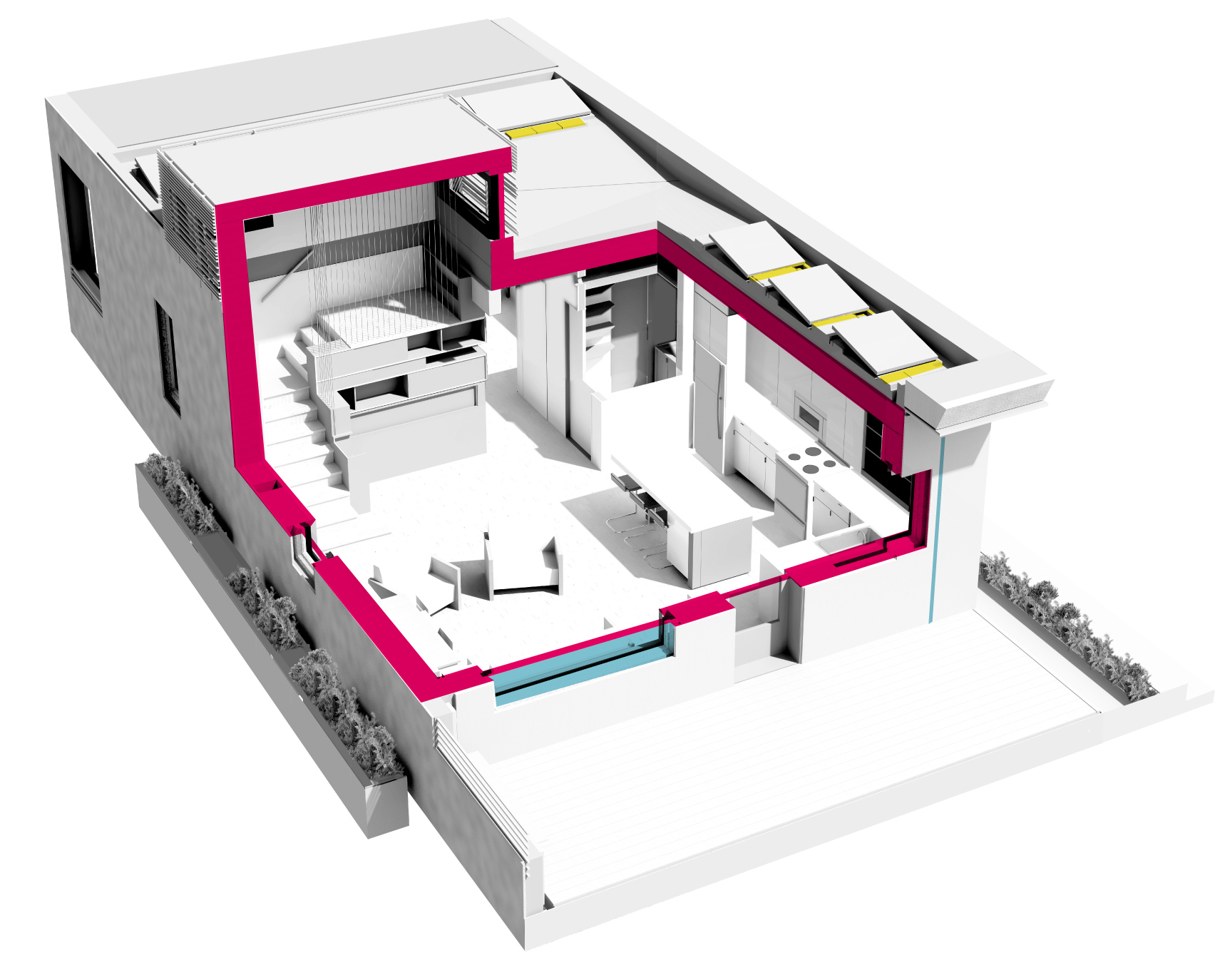

The design process was driven through program adjacencies creating synergy between academic programs with new spatial relationships. The entrance atrium is envisioned as a connector: its triple height stair will create new physical relationships with the adjacent science building, Dauby Hall and nearby Besse Library while also acting as a social connector providing needed lounge, study and meeting place for students. Additional phases plan for a farther expanded grand atrium, serving to act as Ursuline’s central social hub, which will be the campus’ largest gathering space. Additionally, new chemistry, biology, nursing, art labs and offices will encourage a culture of collaboration between previously disparate programs.

The new Center for Creative and Healing Arts is designed to raise standards for healthy, comfortable environments. The building’s layout and solar orientation of the fenestration influenced the design, aiming to maximize views and daylighting while minimizing summer solar heat gain.

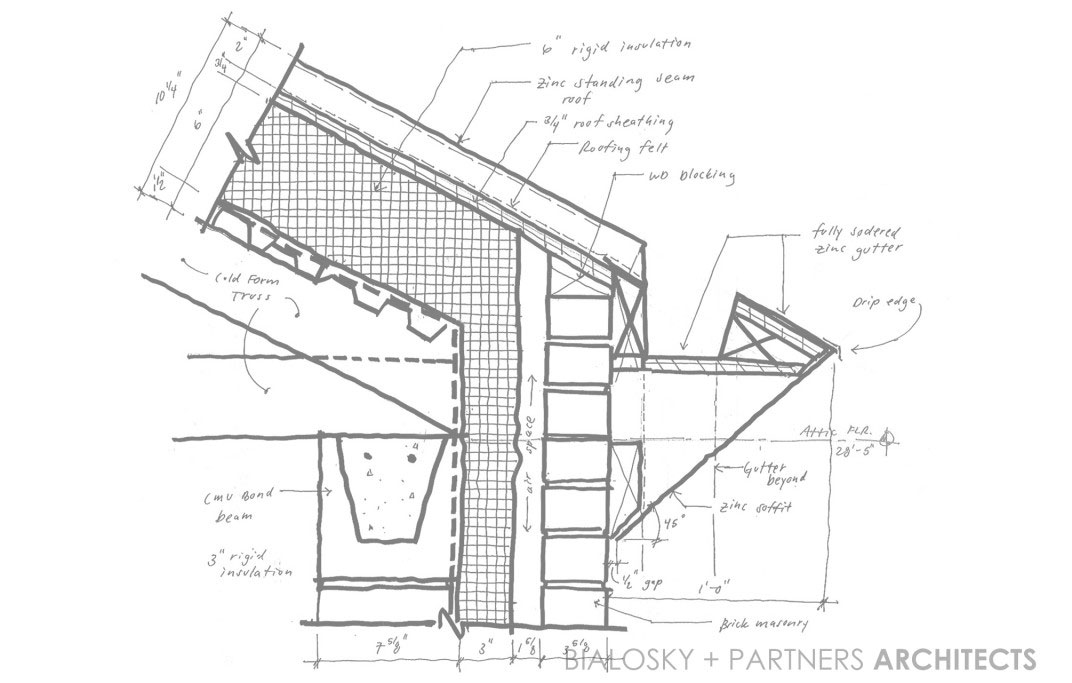

Precise detailing allows minimal thermal bridging, which lends to a high performing building enclosure that minimizes energy usage throughout the year. The CCHA’s building enclosure systems are designed to outperform ASHRAE 90.1 energy code metrics by 50%. The Variable Refrigerant Flow HVAC system is designed to outperform ASHRAE 90.1 by 55%, and a LED lighting package with daylight harvesting bests the code by 20%.

The Center for Creative and Healing Arts, the first implemented phase of the Ursuline College master plan, projects a future of forward looking, contextual, well-crafted, and environmentally responsible architecture that gives physical shape to Ursuline College’s core mantra of Values, Voice and Vision.